Can sustainable plastics clean our plastic-polluted water?

April 21, 2022

From Carolina Arts & Sciences magazine, written by Delene Beeland

Dr. Frank Leibfarth

Inventing a new kind of plastic to remove plastic pollution from our drinking water may sound counterintuitive. But for Frank Leibfarth, PhD, it makes perfect sense.

Leibfarth, an assistant professor of chemistry, invented a synthetic resin material that is highly effective in lab experiments at removing polluting chemical components known as PFAS — which stands for per- and polyfluoroalkyl substances — from drinking water.

PFAS are created in the commercial production of many products and coatings that repel water and stains, from stain-resistant fabrics to your favorite nonstick frying pan to takeout food boxes.

Leibfarth’s polymer plastic material is so innovative that Popular Science named him to its “Brilliant 10” list in 2021. The honor recognizes early-career scientists and engineers nationwide engaged in transformative work through innovative approaches to global issues.

Dr. Orlando Coronell

The North Carolina General Assembly also took note and recently allocated $10 million in funding for Leibfarth’s laboratory — and that of his collaborator, Orlando Coronell, PhD, associate professor of environmental sciences and engineering at the UNC Gillings School of Global Public Health — to scale up the new resin for use in public water utility systems.

N.C. Senator Michael Lee, who represents New Hanover County, championed inclusion of the funding boost in last fall’s budget. The North Carolina Collaboratory, established by the General Assembly in 2016, has helped to raise awareness for the importance of PFAS research and testing through the NC PFAS Testing Network, which includes Leibfarth and Coronell.

“Early lab results suggest these resins developed at UNC outperform anything else on the market by a factor of two and, in some cases, remove almost 100% of PFAS compounds,” said Lee. “If this technology works at scale, it will be a significant tool to mitigate PFAS exposure in N.C.’s drinking water and, frankly, that of the world.”

GenX pollution is affecting the lower basin of the Cape Fear River. (Photo by Liam McPherson)

Several N.C. waterways are severely contaminated with PFAS due to industrial chemicals, such as the well-documented case of GenX (a type of PFAS) pollution by an industrial plant in the lower basin of the Cape Fear River. The river provides drinking water for an estimated 355,000 North Carolinians downstream of the plant.

Leibfarth and Coronell hope the new resin will clean up the Cape Fear and other rivers, too. Better yet, they hope it will bring environmental equity to lower-income families who are disproportionately affected by PFAS pollution.

“PFAS pollution is a problem in N.C., but it’s also an international problem,” Leibfarth said. “Our work will benefit the state, but

it will also, hopefully, have global benefits.”

REDUCE, BUT ABOVE ALL, REINVENT

For many years, the pro-environment message has been to move away from plastics due to their legacy of harm. But Leibfarth’s philosophy is more nuanced. And it helps explain why he believes a next-generation sustainable plastic will save us from plastics of the past.

Leibfarth said that while we should all try to reduce the amount of plastic we use personally, there are some applications in life where plastics are better for the environment.

Yes, you read that right.

“Take cars,” he explained. “Today’s vehicles contain more plastic than those made several decades ago. This means they are lighter and burn less fuel. Or, if you drive an electric car, use fewer electrons.”

Still most traditional plastics biodegrade poorly. Their molecular legacy is expected to live on as “forever chemicals” that pollute our soil, water and oceans for millennia.

PFAS are particularly troubling because they “accumulate in the environment, and they don’t biodegrade. They will be there for thousands of years, and we just keep making more,” Leibfarth said. “Worse, they can cause health effects even at low levels of exposure.”

While understudied, exposure to these chemicals is tied to disruption of the endocrine system and some cancers. But it’s not just those living near polluting factories who are affected. PFAS pollution is so pervasive that it’s in our water, our food — and bioaccumulates in each of us.

“The dangerous part of these chemicals is their combination of toxicity and longevity,” Leibfarth said.

Despite the missteps of plastics past, Leibfarth believes next-generation sustainable plastics are the solution.

“I call myself a polymer chemist,” Leibfarth said. “All plastics are polymers, but not all polymers are plastics. Using our ability to build polymer materials from the ground up, and our commitment to sustainability, we saw this opportunity where we felt we could make a contribution to water purification. That’s what led us to make these materials for PFAS remediation.”

SCALING UP: FROM THE LAB TO PUBLIC WATER UTILITIES

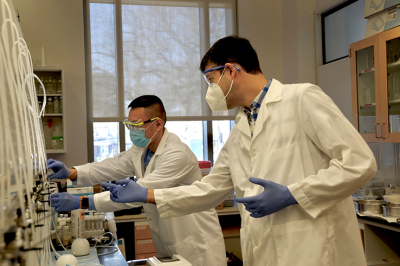

Postdoctoral associate Guan Pin “Nick” Chew, left, joins Orlando Coronell in the lab. (Photo by Jennie Saia)

While Leibfarth has focused on designing the structural properties of the new material, collaborator Coronell from the Gillings School has focused on how to apply it. He is examining how to use the new resin in engineered systems where its performance can be measured and evaluated. The funding boost from the state will aid in scaling the material from testing at the lab bench to real-world testing in three locations across the state: two public water treatment facilities and one aquifer.

Despite the pair’s promising findings to date, there are challenges to overcome.

Leibfarth’s immediate challenge will be to overcome manufacturing hurdles. His lab has created 40 grams of the polymer at a time, but he will need to scale up to at least 400 kilograms for testing in the water treatment facilities.

Second, Coronell will take the system devised for running tests in the lab and re-engineer it for use in a water treatment facility. There are many different variables to account for, he said. A big question is how the material’s structure will affect its performance at scale.

“From the size of the beads and their structure to the content of organic matter and other ions in the water to how fast the water flows through the column — it all matters,” Coronell said.

There is also the broad nature of PFAS molecules themselves. More than 5,000 chemicals fall under the PFAS umbrella, and these are largely grouped into short and long-chain PFAS. The Environmental Protection Agency urged industry to voluntarily cease producing long-chain PFAS in the mid-2000s. Industry’s response was to move to short-chain PFAS, but emerging evidence indicates that these are just as bad for human health and are even more difficult to remove from the environment.

“They tend to leak through state-of-the-art resins,” Leibfarth said. “We were finding breakthrough of the short-chain PFAS in simulations of six months.” In contrast, tests of long-chain PFAS found simulated breakthroughs in 18 months.

Coronell’s added challenge is thinking through the resin material’s life cycle.

“What happens when you get through its useful life? Can we transform it to its prior state and render it useful again?” he asked. “These are important considerations in terms of whether these new technologies can be used or not at scale.”

The next step will be to run experiments in real-world situations and in real time. Testing and evaluation at the water treatment plants will span several months to a year, Coronell said.

“But first we want to ensure we have a resin bead that will actually work,” he added. “Before testing at pilot scale at a water treatment plant, we will continue to work at laboratory scale with additional equipment, resources and water samples to ensure we have something that is worth testing at scale.”

The Institute for Convergent Science will be working with the North Carolina Collaboratory to support this project. ICS was also an early investor in the PFAS project and seeks — along with Innovate Carolina — to help bring it across the finish line.

“We would not have taken on the challenge if we did not think it was doable,” Leibfarth said. “But we could not have gotten to this next step without this new funding.”

Contact the UNC Gillings School of Global Public Health communications team at sphcomm@unc.edu.